UNL Materials Research Science and Engineering Center (2014)

The University of Nebraska MRSEC “Polarization and Spin Phenomena in Nanoferroic Structures” (P-SPINS) carries out collaborative research on new magnetic materials and structures at the nanometer scale, with the aim of developing fundamental understanding of their properties and related phenomena. Recent pioneering discoveries by the UNL MRSEC researchers have broadened the Center’s scope and positioned its investigators to build the sustainable potential for exploring new frontiers in materials and nanoscience well into the future. A particular emphasis is made on studies of new ferroic materials and structures aimed at developing the fundamental understanding of their properties and related phenomena important for information processing and storage, energy harvesting, and advanced electronics. P-SPINS relies on interdisciplinary collaborations, extensive use of shared facilities, partnerships with national laboratories and international institutions and interactions with industrial companies to leverage the expected scientific innovations for potential technological advances.

As an integral part of the Center, P-SPINS offers interdisciplinary training for the next generation of materials scientists and engineers by providing regional four-year institutions experience and tools to improve their materials science programs and curricula, offering opportunities for middle- and high-school teachers and their students to learn about materials science, and by addressing pre-college segments of the educational pipeline via targeted outreach activities.

Nanostructured copolymers with semicrystalline hydrophobic domains prepared by transition metal catalysis (Seed 1)

The Seed 1 group seeks to fully develop the synthesis of linear, random poly(ethylene-co-X) materials possessing, for instance, ester, acid, or anhydride functionality directly from industrial monomers using a robust family of transition metal catalysts discovered by us. The self-assembly of the resulting amphiphilic macromolecules can be driven by crystallization of hydrophobic polyolefin domains, in both bulk and solution, leading to nanostructured morphologies distinct from those driven by interblock repulsion, and the scalable routes we will develop to substantial quantities of these amphiphilic materials will facilitate detailed exploration of this self-assembly behavior.

Principal Investigators

Brad Carrow (Chemistry)

Richard Register (Chemical and Biological Engineering)

* This seed is inactive.

Seed 4 (Round 1): Direct Deposition of Catalysts on Porous Metallic Foams for Efficient CO2 Electroreduction

Fikile R. Brushett, Assistant Professor, Department of Chemical Engineering

The development of energy efficient carbon dioxide (CO2) electroreduction processes would simultaneously curb anthropogenic CO2 emissions and provide sustainable pathways for fuel generation. While significant efforts have focused on heterogeneous CO2 electroreduction to products such as carbon monoxide, formic acid, and methanol; no process has been able to demonstrate both high energetic efficiencies (≥ 60-70%) and high current densities (≥ 150 mA/cm2). A key challenge is translating our investment in performance nanomaterials to meso- and microarchitectures within electrochemical cells under realistic operating conditions. Here we propose to develop microporous metal foam electrodes with nanostructured electrocatalysts directly deposited onto the foam surface for high-performance CO2 conversion. Metal foams hold two key advantages: 1) their porous nature facilitates extended tunable electrochemical interfaces without sacrificing transport of reactants and ions; and 2) they can act as a conductive substrate for the direct deposition of highly-active surface alloys eliminating the need for conductive additives and binders (which may degrade or promote side reactions). We will focus on CO-selective catalysts (e.g ., Ag, Au) as this represents the simplest CO2 conversion reaction and has been demonstrated at moderate efficiencies (albeit at low currents). Direct deposition enables ground-up construction of nanostructures using bath conditions (e.g. composition), delivery mechanism (e.g., diffusive, convective), and applied potential (for electrodeposition) as tools to control structure, phase, and surface characteristics. We will systematically investigate the structure-activity-stability relationships of the deposited catalysts and electrodes using electroanalytical and physical characterization techniques. Of particular interest will be catalysts deposited under transport limiting conditions (desirable for high-throughput manufacturing) and catalyst-substrate interactions (determines durability). The success of this project would enable efficient CO production at the large-scale which, when coupled with hydrogen generation from renewables enables the carbon-neutral synthesis gas production needed to generate liquid fuels for heavy duty transportation applications.

Brown's Center for Advanced Materials Research (1996)

The Materials Research Science and Engineering Center (MRSEC) at the Brown University supports interactive research in one interdisciplinary group focusing on advanced materials for structural and electronic applications. The research group emphasizes the development of a new generation of capabilities for measuring and modeling mechanical response at the microscopic level. Advanced measurement and modeling techniques will be used. The goal will be to develop methodologies to realize predictive capabilities and to understand the performance and limitation of particular microstructures at micron and atomic length scales. The MRSEC supports the development, operation and maintenance of shared experimental facilities for materials research. It provides seed funding for exploratory research and fosters research participation by undergraduates. The Center develops educational modules consisting of interactive demonstrations and laboratory projects to be used by mathematics and science teachers. The MRSEC also supports enhanced collaboration with industry, shared experimental facilities that also support research not directly funded by the MRSEC, and seed funding for exploratory research. The Center currently supports about 12 senior investigators, 2 postdoctoral research associates, 3 technician or other professional, 12 graduate students, and 4 undergraduates. The MRSEC is directed by Professor Rodney Clifton. %%% The Materials Research Science and Engineering Center (MRSEC) at the Brown University supports interactive research in one interdisciplinary group focusing on advanced materials for structural and electronic applications. The research group emphasizes the development of a new generation of capabilities for measuring and modeling mechanical response at the microscopic level. Advanced measurement and modeling techniques will be used. The goal will be to develop methodologies to realize predictive capabilities and to understand the performance and limitation of particular microstructures at micron and atomic length scales. The MRSEC supports the development, operation and maintenance of shared experimental facilities for materials research. It provides seed funding for exploratory research and fosters research participation by undergraduates. The Center develops educational modules consisting of interactive demonstrations and laboratory projects to be used by mathematics and science teachers. The MRSEC also supports enhanced collaboration with industry, shared experimental facilities that also support research not directly funded by the MRSEC, and seed funding for exploratory research.

Development of Ultra-Coherent Quantum Materials (IRG 3)

The past decade has seen explosive growth in the area of quantum information science and related quantum enabled technologies. The IRG-3 team is focused on developing ultra-coherent quantum materials, in particular group IV materials such as Si, Ge, SiC, and diamond. Members of the team recently demonstrated that isotopically enriched silicon samples can support electron spin coherence times at least as long as 10 seconds, orders of magnitude longer than other solid state systems. Such isotopic enrichment is not possible in III-V materials, as no spin-0 nuclear isotopes exist for any III-V element. Moreover, work by team members has also shown that single electrons can be routinely isolated in Si devices, paving the way for studies of quantum coherence at the single spin level. The team includes experts on the growth and characterization of these materials, device design and measurement, and superconducting devices which can couple to the electron spins.

Co-Leaders

S. A. Lyon, co-leader (EE)

A. A. Houck, co-leader (EE)

Senior Investigators

Nathalie de Leon (EE)

J. C. Sturm (EE)

J. M. Taylor (Physics, Joint Quantum Institute/U. Maryland)

Jeff Thompson (EE)

Collaborators

J. M. Chow (IBM Watson Research Center)

Chris Dries (United Silicon Carbide)

M. F. Gyure (HRL Laboratories)

C.-W. Liu (National Taiwan University)

B. Lovett (Heriot-Watt University)

J. Morton (University College London)

J. Pomeroy (NIST)

T. Schenkel (LBNL)

C. Tahan (Laboratory for Physical Sciences)

M. Thewalt (Simon Fraser)

Guido Burkard (Konstanz University)

Marcelo Maialle (University of Campinas)

Engineered Multiblock Polymers

Engineered Multiblock Polymers designs, prepares, characterizes and employs block polymers containing more than two chemically distinct segments to enable a rich array of sophisticated technologies using these nanostructured hybrid materials. The group establishes fundamental knowledge concerning the complex interplay between synthesis, structure, properties, and processing in these materials and focuses their research efforts on multidomain aqueous assemblies for innovative biomedical applications, tailored membrane materials for advanced separations, and inventive coating and extrusion processes that facilitate practical applications of new multiblock-based materials.

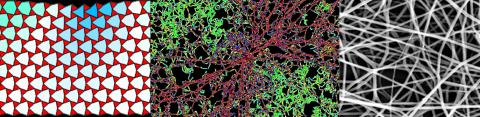

Structural Chemo-Mechanics of Fibrous Networks

Structural Chemo-Mechanics of Fibrous Networks aims to develop a new field of network chemo-mechanics by understanding and harnessing the structural, chemical, and mechanical complexity inherent in fibrous networks. Fibrous networks are ubiquitous in biology but are underexplored in materials science. The team will create and characterize new fibrous materials with structural chemo-mechanical properties, and it will develop theory and models to enhance understanding of them. Specifically, we aim to synthesize materials in which spatially localized chemical reactions are controlled through management of local fibrous network structure. This local chemical control can occur by focusing applied macroscopic stress to targeted regions in the material; this phenomena enables us to concentrate or align chemical species with specific reactant and catalyst sites, and thereby alter their reaction kinetics. The group will thus lay foundations for materials with stress-reinforcing and self-renewal capabilities and materials with an expanded range of non-linear elastic responses to large multiaxial strains. The new concepts are useful for advanced fibers, adhesives, elastomers, textiles, and scaffolds for tissue repair and regeneration.

Emergent Properties Resulting from Constraints

This IRG includes three thrust areas. These thrust areas are intimately related in several ways: the overlapping participation of the investigators, the common experimental methods and biopolymer materials, and the common theme of materials under constraint resulting in new properties. More important, they explore

this common theme on several levels of complexity. The first thrust deals with constraints on individual molecules, the second with the structure of large condensed arrays of molecules, and the third with the spatial and temporal organization of "active matter", dynamical arrays of interacting objects. All three levels are vital to understanding living systems, and combined, they have the potential for creating novel nano-structured material systems.

Polymers in a crowded and confined environment

The first thrust area will study the effects of localization of biopolymers both in vivo and in vitro,

bridging the gap between traditional biological and physical studies. In cells, confinement of

macromolecules to very small and crowded volumes has major consequences for structure and dynamics.

We will explore this rich and important subject that is crucial to biological function. We will use

microfluidic devices for in vitro studies of the confinement of DNA, microtubules and actin, correlating

the results with fluorescence microscopy studies of processes involving DNA dynamics in yeast cell

nuclei.

Frustration in chiral self-assembly

The second thrust area will study the effects of chirality in frustrating long range order in both

crystals and membranes, resulting in complex new structures. Although frustration can result in

macroscopic modulated phases, like the beautiful twisted grain boundary phases and the cholesteric blue

phases, it can also lead to finite self-limiting self-assembled structures. Self assembly of molecular

components into ordered arrays is a dominant theme in materials science. However, chirality, the twisted

internal structure of the elementary units, can result in twisted aggregates not compatible with long range

order. The result can be novel structures such as twisted filaments and ribbons, and complex arrangement

of membranes and pores. This may produce simple models for some cell components, which are also

constructed by self-limiting self-assembly.

Active matter under confinement

The third thrust area, perhaps the most exciting and novel, will study "active matter," with the initial

focus on two examples which sound quite different, but have fundamental concepts in common, and are

capable of producing similar spatial and temporal patterns. The first is the dynamical nematic liquid

crystal, composed of actin filaments that are constantly polymerizing at one end, and de-polymerizing at

the other, leading to the travel of each filament relative to its surroundings. We will study the resulting

formation of spatial and temporal patterns, some of which play an important role in cellular dynamical

processes, such as cell division. The second is a dense array of droplets each containing an oscillating

chemical reaction, either a controlled array produced by microfluidics or randomly packed nano-droplets

in a microemulsion. Interactions among the droplets by diffusion of reagents produce a rich variety of

pattern formation and temporal self organization, which we will study by careful variation of the

parameters of these systems. These will be the first precisely controllable experimental model systems of

active matter ever formulated and analyzed, an important innovation in this exciting new area.

Engineering Materials and Techniques for Biological Studies at Cellular Scales

This IRG focuses on understanding the mechanical properties of the cell, a central object of study in biology, and its structural components. Tools and techniques necessary to study problems in biology at the scale of a single cell are being developed using the materials expertise of MRSEC participants. This IRG has established the use of soft lithography and patterning in the study of the behavior of individual cells.

Showing 2401 to 2410 of 2586